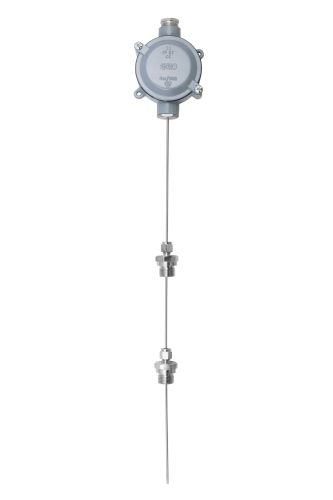

Temperature sensor type – RST/TST – M

Product description

Download product sheet in PDF

[CONFIGURATOR]

Application:

Temperature sensor for stern tubes. The RST/TST – M is a stern tube bearing sensor.

Mechanical connection: 2 adjustable couplings

Properties:

• Pt100 resistance thermometer in acc. with DIN IEC 751

• Measuring insert: fixed

• Mechanical and thermal stress in accordance with DIN 43763

• Process attachment: adjustable coupling

• Constructed so as to have the greatest possible accuracy and durability during demanding operating conditions that means:

– It is robust

– It is flexible/ bendable (do not bend the first 50mm!)

– It has a quick reaction time

• Outer protective sheath: acid-proof steel

• IP67

• Electrical connection: connection box

• Mechanical connection: 2 adjustable couplings

• Marine approved by: DNV, LR, GL, NK, RINA, ABS and BV